How To Measure A Threaded Hole . use a nut thread gauge. for external threads: understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. The two primary categories we. (8 equally spaced points) •. use auto circle with pitch equal to the pitch of the thread. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. The hits will all ride at the same place on the thread, but won't necessarily be. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped.

from www.youtube.com

(8 equally spaced points) •. The two primary categories we. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. use auto circle with pitch equal to the pitch of the thread. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. use a nut thread gauge. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. for external threads: The hits will all ride at the same place on the thread, but won't necessarily be.

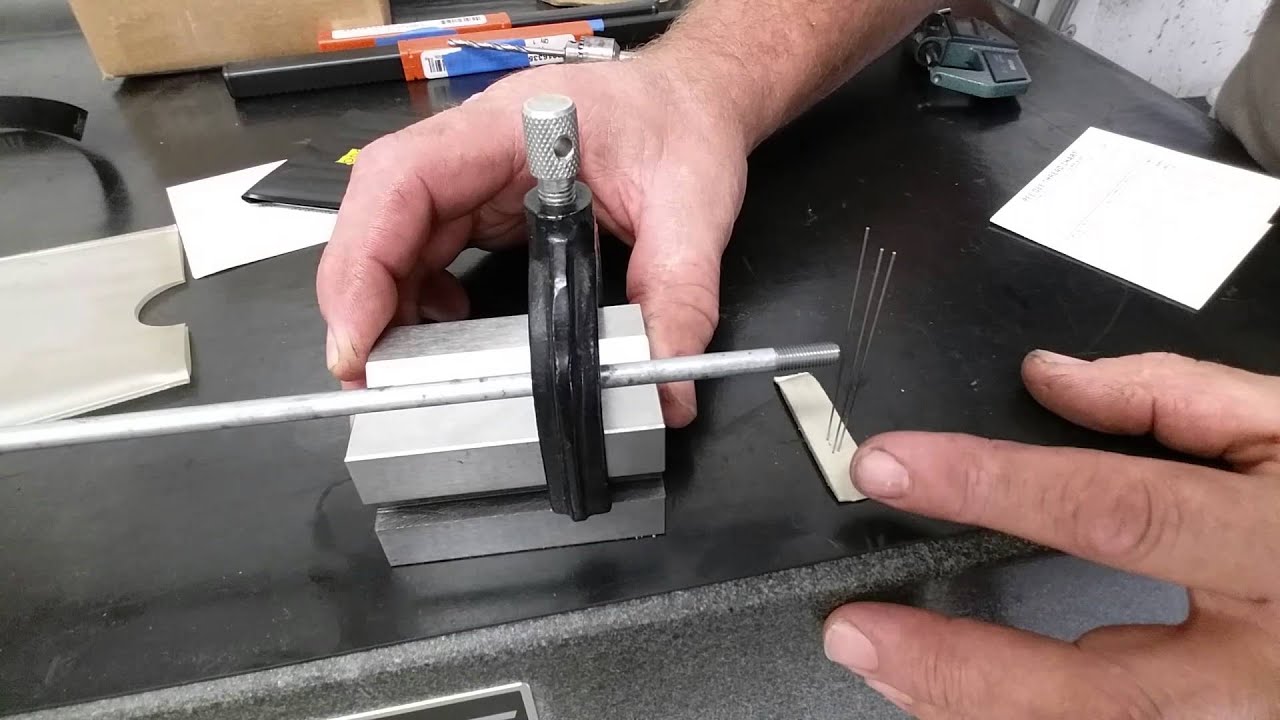

Using the 3 wire method for measuring thread pitch. YouTube

How To Measure A Threaded Hole The two primary categories we. The hits will all ride at the same place on the thread, but won't necessarily be. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. use a nut thread gauge. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. for external threads: direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. The two primary categories we. use auto circle with pitch equal to the pitch of the thread. (8 equally spaced points) •.

From sofiadonnell.z13.web.core.windows.net

Nut And Bolt Thread Sizes How To Measure A Threaded Hole direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. use a nut thread gauge. a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. use auto circle with pitch equal to the pitch of the. How To Measure A Threaded Hole.

From www.slideserve.com

PPT Screw Threads PowerPoint Presentation, free download ID6115727 How To Measure A Threaded Hole The hits will all ride at the same place on the thread, but won't necessarily be. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. for external threads: use a nut thread gauge. (8 equally spaced points) •. use auto circle with pitch equal to the pitch of the thread. . How To Measure A Threaded Hole.

From cetfjavu.blob.core.windows.net

Standard Vs Metric Threads at Jarrod Rowe blog How To Measure A Threaded Hole measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. use a nut thread gauge. for external threads: direct probing of thread use zeiss pcm thread routine • measure circles at. How To Measure A Threaded Hole.

From theoreticalmachinist.com

Metric screw thread M Profile calculator How To Measure A Threaded Hole for external threads: The two primary categories we. use a nut thread gauge. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. use auto circle with pitch equal to the pitch of the thread. (8 equally spaced points) •. a short but valuable lesson on how. How To Measure A Threaded Hole.

From www.youtube.com

Using the 3 wire method for measuring thread pitch. YouTube How To Measure A Threaded Hole (8 equally spaced points) •. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. The hits will all ride at the same place on the thread, but won't necessarily be. for external threads: . How To Measure A Threaded Hole.

From unugtp.is

How To Measure Thread Size Metric UNUGTP News How To Measure A Threaded Hole (8 equally spaced points) •. use a nut thread gauge. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. measure hole diameter and depth and adjust cutting depth to match the. How To Measure A Threaded Hole.

From rapidaxis.com

Threaded Hole Design Guide Rapid Axis How To Measure A Threaded Hole direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. (8 equally spaced points) •. The two primary categories we. use a nut thread gauge. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. use auto circle with pitch. How To Measure A Threaded Hole.

From insize.co.id

INSIZE 4676 Threaded Hole Location Gauge For CMM/Caliper (Spline shaft How To Measure A Threaded Hole The hits will all ride at the same place on the thread, but won't necessarily be. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. understanding the nuances between different types of threaded holes. How To Measure A Threaded Hole.

From www.youtube.com

Dimensioning Hole Depth YouTube How To Measure A Threaded Hole a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. The hits will all ride at the same place on the thread, but won't necessarily be. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. direct probing of thread use. How To Measure A Threaded Hole.

From www.protolabs.com

Threading Coil Inserts How To Measure A Threaded Hole use auto circle with pitch equal to the pitch of the thread. The hits will all ride at the same place on the thread, but won't necessarily be. (8 equally spaced points) •. The two primary categories we. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. measure hole diameter. How To Measure A Threaded Hole.

From lookatme-janeandrobert.blogspot.com

How To Measure Thread Size Of A Bolt Bolt Nut Screw Thread Size How To Measure A Threaded Hole a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. use auto circle with pitch equal to the pitch of the thread. measure hole diameter and depth and. How To Measure A Threaded Hole.

From www.eng-tips.com

THREADED HOLE WITH COUNTERBORE CALLOUT Aeronautic & Space engineering How To Measure A Threaded Hole Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. The hits will all ride at the same place on the thread, but won't necessarily be. use a nut thread gauge. use auto circle with pitch equal to the pitch of the thread. a short but valuable lesson on how to quickly. How To Measure A Threaded Hole.

From www.protolabs.com

Threading Standard Holes How To Measure A Threaded Hole understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. (8 equally spaced points) •. direct probing of thread use zeiss pcm thread routine • measure circles at both ends of threaded hole. use auto circle with pitch equal to the pitch of the thread. a short but valuable lesson. How To Measure A Threaded Hole.

From www.slideserve.com

PPT Mechanical Engineering Drawing MECH 211/M PowerPoint Presentation How To Measure A Threaded Hole The two primary categories we. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. (8 equally spaced points) •. a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. The hits will all ride at the same place on the thread,. How To Measure A Threaded Hole.

From www.coloringupdate.com

How To Draw Threaded Hole In Autocad 2D at How To Draw How To Measure A Threaded Hole measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. The two primary categories we. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. (8 equally spaced points) •. direct probing of thread use zeiss pcm thread routine • measure circles at. How To Measure A Threaded Hole.

From saratov.myhistorypark.ru

NPT Thread Dimensions A Complete Guide EngineerExcel, 47 OFF How To Measure A Threaded Hole for external threads: The two primary categories we. understanding the nuances between different types of threaded holes is fundamental for engineers and machinists alike. (8 equally spaced points) •. use a nut thread gauge. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. The hits will all. How To Measure A Threaded Hole.

From homerepairgeek.com

Bolt Hole Sizes Chart with Complete Guide Home Repair Geek How To Measure A Threaded Hole The hits will all ride at the same place on the thread, but won't necessarily be. use a nut thread gauge. Place the ruler perpendicular to the threaded shaft, aligning the edge with one thread peak. measure hole diameter and depth and adjust cutting depth to match the required thread depth, ensuring the threaded. understanding the nuances. How To Measure A Threaded Hole.

From mavink.com

Dimensioning Hole Patterns How To Measure A Threaded Hole The hits will all ride at the same place on the thread, but won't necessarily be. a short but valuable lesson on how to quickly determine the hole size for a 60 degree, internal, single pointed or tapped. The two primary categories we. (8 equally spaced points) •. direct probing of thread use zeiss pcm thread routine •. How To Measure A Threaded Hole.